Flurine®M Series Fluoroelastomer

| Categories | Fluoroelastomer FKM |

|---|---|

| Brand | Zheflon PVDF & Flurine FKM Manufacturer |

| Model | M Series |

| Features | Narrow molecular weight distribution |

| Uses | Shaft seals, gaskets, O-rings, extruded shapes |

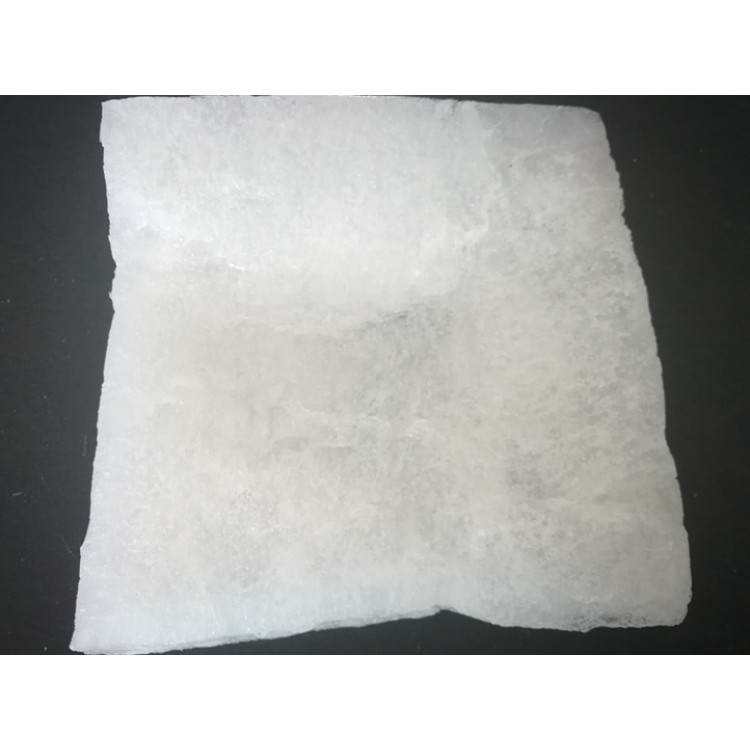

| Forms | White or light-yellow flake |

| Update Time | Mar 24,2025 |

Flurine® M series is a relatively narrow molecular weight fluoroelastomer copolymerized with vinylidene fluoride (VF2) and hexafluoropropylene (HFP). It is commonly used in the automotive, hydraulic, electrical and chemical industries. It has outstanding mechanical properties, very low compression set rate and moderate scorch time. It has excellent resistance to oils, fuels, aliphatics, aromatic hydrocarbons, lubricants and most inorganic acids. General | |||||

Features | Narrow molecular weight distribution | ||||

Uses | Shaft seals, gaskets, O-rings, extruded shapes | ||||

Forms | White or light-yellow flake | ||||

Items | Typical Value | Test Method | |||

M228 | M728 | M928 | |||

Physical Properties | |||||

Fluorine Content(mass%) | 66 | 66 | 66 | ||

Density(g/cc) | 1.78~1.84 | 1.78~1.84 | 1.78~1.84 | ASTM D297 | |

Mooney Viscosity | 20~45 | 60~80 | ≥100 | ASTM D1646 ML 1+10 at 121°C | |

Water content(%) | <0.15 | <0.15 | <0.15 | ASTM D 5668 | |

Vulcanization Properties | |||||

T10(s) | <110 | <90 | <70 | ASTM D5289 | |

T90(s) | <240 | <210 | <180 | ASTM D5289 | |

Mechanical Properties | |||||

Tensile strength(MPa) | 14.0 | 14.5 | 15.0 | ASTM D412 Method A | |

100% Modulus | 5.0 | 5.2 | 5.4 | ASTM D412 Method A | |

Elongation at Break(%) | 190 | 180 | 170 | ASTM D412 Method A | |

Tearing Strength(KN/m) | 21 | 22 | 22 | ASTM D624 | |

Hardness, Shore A | 70~80 | 70~80 | 70~80 | ASTM D2240, Type A | |

Compression Set | 16 | 15 | 15 | ASTM D395, Test B 70 hours at 200℃ | |

Air-oven aging | ISO 188 After Dry Heat Aging;70 hours at 230℃ | ||||

Tensile strength change rate(%) | -10 | -8 | -5 | ASTM D412 Method A | |

Elongation at Break change rate(%) | -8 | -6 | -6 | ASTM D412 Method A | |

Hardness change, Shore A | -1 | -1 | -1 | ASTM D2240, Type A | |

Thermal Properties | |||||

TR10(℃) | -17 | -17 | -17 | ASTM D1329 | |

Brittleness Temperature(℃) | -30 | -30 | -30 | ASTM D2137 | |

Chemical resistance Properties | |||||

Resistance to liquids | 3 # standard oil | ||||

Volume change rate(%) | +2 | +2 | +1 | ASTM D471 72 hours at 150℃ | |

Mass change rate(%) | +1 | +1 | +1 | ASTM D471 72 hours at 150℃ | |

Formulation | Curing condition | ||||

Polymer 100 MT carbon black,N990 30 Calcium hydroxide 6 Magnesium oxide 3 Fluorocure-5# 2.5 | Press | Oven | |||

6min at 177°C | 24h at 230°C | ||||

Contact Immediately

- Name

- Tel

- *Title

- *Content