Hubei Production Base

Hubei Production Base

Zhejiang Production Base

Hubei Production Base

Hubei Production Base

Hubei Production Base

Production Base

Production Base

R&D Laboratory

R&D Center

European Service Center

Built and commissioned in 2007, it is a modern, efficient and quality-oriented industrial area. The annual output of this plant can reach 5,000 tons of PVDF and 2,000 tons of FKM.

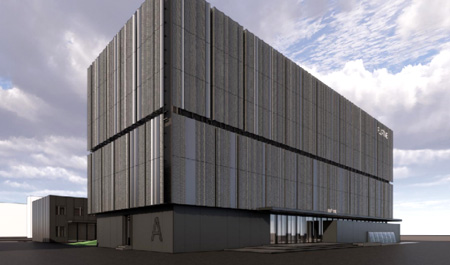

The central control building, a key building has advanced equipment and technology dedicated to the central management and control of all aspects of the production process, with the aim of ensuring efficient production and consistent quality.

The Administration Building is a modern building that serves as the heart of corporate management and administrative affairs, presenting an image of professionalism, efficiency and leadership.

Zhejiang FLUORINE has been awarded the ISO 9001 quality management system certification. This proves that the factory's quality management system complies with international standards and has an effective set of quality management procedures in place to ensure consistency and traceability of the products.

Zhejiang FLUORINE is certified to the ISO 14001 environmental management system. This demonstrates that the plant's environmental management system complies with international standards and is able to identify and manage the environmental risks and impacts associated with business activities.

Zhejiang FLUORINE has met strict requirements in quality management, process control, supply chain cooperation and continuous improvement. The factory ensures that its products meet quality standards by developing and implementing a series of quality management procedures. And it is committed to providing high reliability and consistency of products to lithium battery manufacturers.

25,000 tons per year of PVDF production capacity by July 2023, supporting the development of the national lithium battery automotive industry.

The central control centre, a key building for the central command and monitoring of the production process. It is used to monitor and control all aspects of production in real time.

The Quality Control Building is dedicated to quality inspection and testing of PVDF (polyvinylidene fluoride) and FKM (fluoroelastomer) materials. Equipped with state-of-the-art equipment, it aims to ensure the highest standards of quality and performance of our products.

Hubei FLUORINE has obtained ISO 9001 quality management system certification, indicating that the factory's quality management system complies with international standards and has an effective set of quality management procedures in place to ensure consistency and traceability of products.

Hubei FLUORINE has obtained ISO 14001 certification for its environmental management system, indicating that the plant's environmental management system complies with international standards and is able to identify and manage the environmental risks and impacts associated with business activities.

Hubei FLUORINE has met strict requirements in quality management, process control, supply chain cooperation and continuous improvement. The factory ensures that its products meet quality standards by developing and implementing a series of quality management procedures. And it is committed to providing high reliability and consistency of products to lithium battery manufacturers.