C series FKM

| Categories | Fluoroelastomer FKM |

|---|---|

| Brand | Zheflon PVDF & Flurine FKM Manufacturer |

| Model | C227, C727, C927 |

| Features | Medium molecular weight distribution |

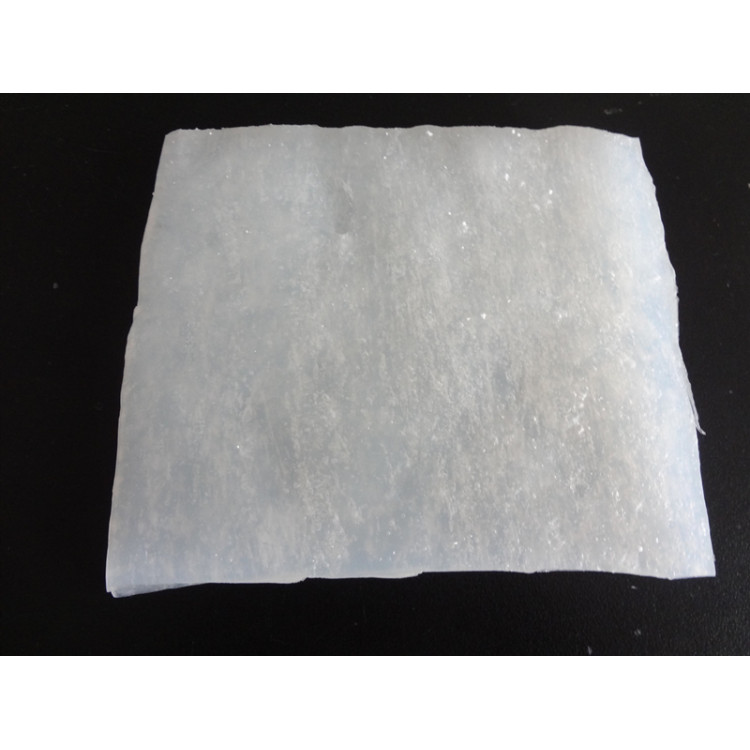

| Forms | White or light-yellow flake |

| Uses | Shaft seals gaskets, O ring, extruded shapes, molded tubing |

| Update Time | Jan 8,2025 |

General | ||||||

|---|---|---|---|---|---|---|

Features | Medium molecular weight distribution | |||||

Uses | Shaft seals, gaskets,O ring, extruded shapes, molded tubing | |||||

Forms | White or light-yellow flake | |||||

Items | Typical Value | Test Method | ||||

C227 | C727 | C927 | ||||

Physical Properties | ||||||

Fluorine Content(mass%) | 66 | 66 | 66 | |||

Density(g/cc) | 1.78~1.84 | 1.78~1.84 | 1.78~1.84 | ASTM D297 | ||

Mooney Viscosity | 20~45 | 60~80 | ≥100 79 | ASTM D1646 ML 1+10 at 121°C | ||

Water content | 0.15 | 0.15 | 0.15 | ASTM D 5668 | ||

Solubility | Soluble in lower ketones and esters | |||||

Vulcanization Properties | ||||||

T10(s) | <70 | <70 | <70 | ASTM D5289 | ||

T90(s) | <140 | <140 | <140 | ASTM D5289 | ||

Mechanical Properties | ||||||

Tensile strength(MPa) | 14.0 | 14.0 | 14.5 | ASTM D412 Method A | ||

100% Modulus | 5.0 | 5.2 | 5.4 | ASTM D412 Method A | ||

Elongation at Break(%) | 190 | 180 | 170 | ASTM D412 Method A | ||

Tearing Strength(KN/m) | 20 | 20 | 20 | ASTM D624 | ||

Hardness, Shore A | 76 | 76 | 76 | ASTM D2240, Type A | ||

Compression Set | 17 | 17 | 17 | ASTM D395, Test B 70 hours at 200℃ | ||

Air-oven aging | ISO 188 After Dry Heat Aging;70 hours at 230℃ | |||||

Tensile strength change rate(%) | -12 | -10 | -8 | ASTM D412 Method A | ||

Elongation at Break change rate(%) | -8 | -6 | -5 | ASTM D412 Method A | ||

Hardness change, Shore A | -2 | -2 | -1 | ASTM D2240, Type A | ||

Thermal Properties | ||||||

Glass Transition Temp, Tg(℃) | -20 | -20 | -20 | ASTM D1329 | ||

Brittleness Temperature(℃) | -30 | -30 | -30 | ASTM D2137 | ||

Chemical resistance Properties | ||||||

Resistance to liquids | 3 # standard oil | |||||

Volume change rate(%) | +2 | +2 | +1 | ASTM D471 72 hours at 150℃ | ||

Mass change rate(%) | +1 | +1 | +1 | ASTM D471 72 hours at 150℃ | ||

Formulation | Curing condition | |||||

Polymer 100 MT carbon black,N990 30 Calcium hydroxide 6 Magnesium oxide 3 Fluorocure-5# 2.5 | Press | Oven | ||||

6min at 177°C | 24h at 230°C | |||||

Contact Immediately

- Name

- Tel

- *Title

- *Content